Examining the environmental footprint of electronics recycling

As part of our mission to change how products are made, we’re taking a closer look at how to make the most of the materials in our phones when they reach the end of their useful lives. As you might suspect, recycling is a big part of the answer. In a series of blog posts, we’ve been talking about different aspects of electronics recycling, including product design and legislation.

While recycling offers a wide range of benefits for a circular economy, it’s not the “ultimate solution” as it’s often made out to be. For example, it isn’t possible to reclaim all of the original materials used to make a smartphone. In our last blog post of this series, we explored three different scenarios for recycling the Fairphone 2, looking specifically at how much material was recovered or lost. In addition, electronics recycling requires a great deal of energy – meaning that recycling comes with an environmental cost. So in this post we’ll be talking about the environmental impact of recycling, and how product design can help us reduce this impact.

Three routes for electronics recycling

Before we jump into anything new, let’s start with a quick recap of the information we’ve already shared: With on-going materials research, we’re going above and beyond legal requirements (and industry norms!) to understand the best way to recycle smartphones. Earlier this year, recyclability experts Dr. Antoinette van Schaik (MARAS B.V.) and Prof. Dr. Dr. h.c. Markus A. Reuter (Helmholtz Association, Freiberg, Germany) studied the design of the Fairphone 2 and its implications for recycling. Their research included analyzing three different recycling scenarios:

- Smelting and metal refining

Feeding whole Fairphones into a high-temperature metallurgical furnace, recovering mainly metals, alloys, inorganic compounds and energy. - Dismantling

Separating Fairphone 2 modules and putting them through the most suitable metallurgical and plastic recovery processes. - Shredding and sorting

Removing the battery and feeding the rest of the phone through a cutting mill. The resulting scrap is then separated into the relevant processing streams (metallurgy, refining and plastic recovery).

After examining the high-level findings of the research, we came to the conclusion that route 2 (dismantling and metallurgy) was the best recycling approach for Fairphone 2 in terms of recovering materials. This was based on the fact that this route offered the best balance between material recovery by weight, as well as the best variety of recovered metals and reusable plastics. For more information, please read the first blog post in this series.

How does recycling impact the environment?

But the weight and amount of materials recovered is only part of the equation. As we mentioned above, recycling doesn’t only come with benefits – it also has environmental costs. Therefore, we also needed to analyze which recycling route would be best for the environment.

As expected, these calculations were far from simple. Our experts had to deal with a complex product containing a huge range of materials, plus complete a detailed analysis of energy use at each step of the various recycling processes. With assistance from GaBi and HSC Sim software, their simulation model was able to reveal the environmental footprint of each process.

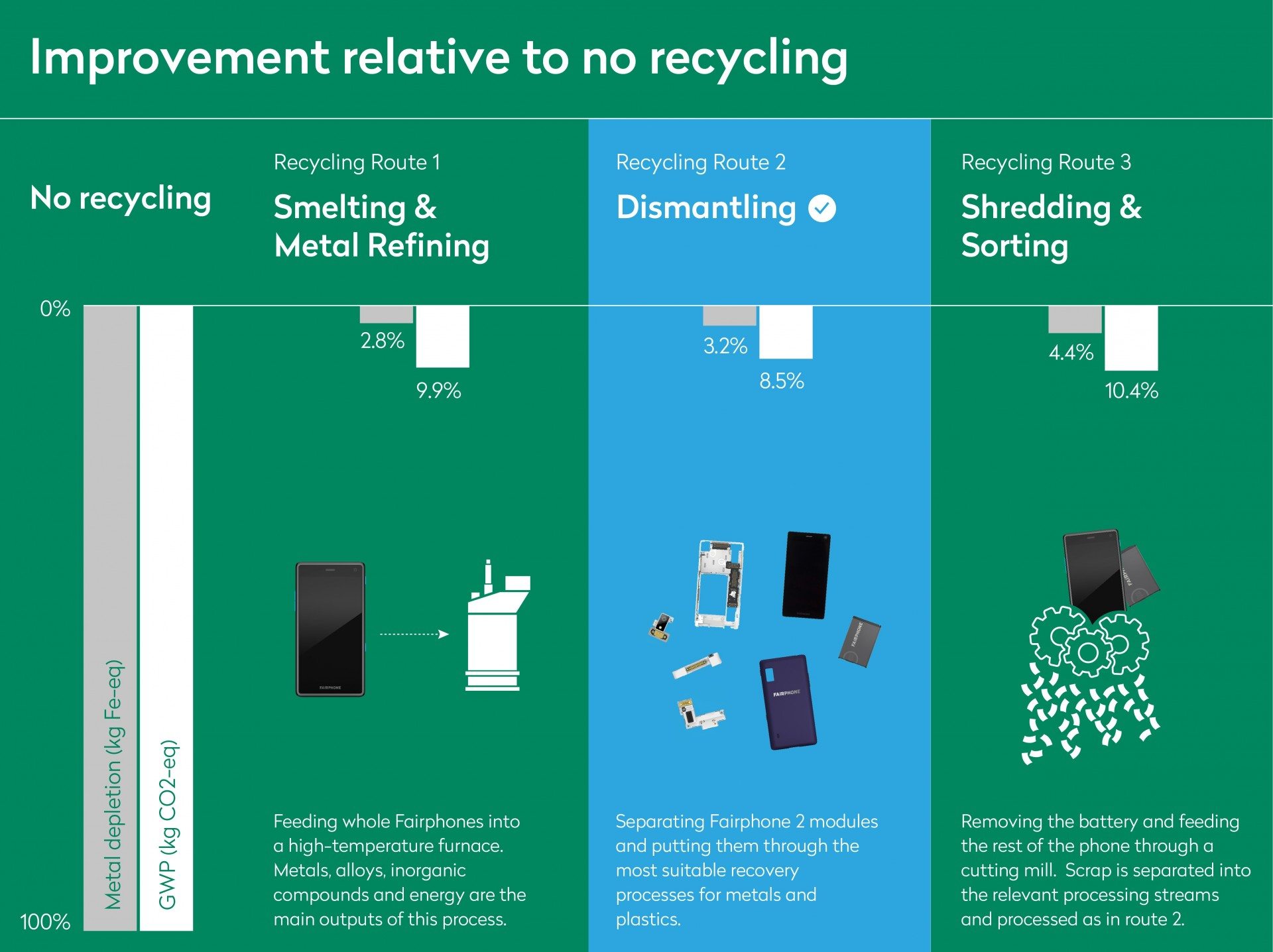

So, how do the three routes compare? Looking at the figure below, you can see that route 1 (total smelting) has the least metal depletion, but also has the second-highest rate of global warming potential (GWP, measured by CO2 equivalent). Route 2 (dismantling) results in greater metal depletion than route 1, but has a lower GWP. Finally, route 3 (shedding/sorting) has the least desirable results, both in terms of metal depletion and GWP.

Figure 1: Comparison of improvement of each recycling route, relative to no recycling.

In addition to energy use and metal depletion, our experts also considered the role of plastics. While plastics can sometimes be recovered in a reusable form, they can also be used as fuel or reductant during the recycling process. So plastics can actually create energy and offer an environmental advantage in the recycling routes. Route 1 uses all the plastic as fuel or reductant, meaning none of the plastics are recovered after recycling. Route 2 dismantles the Fairphone 2 modules. As a result, some of the plastic can be used as fuel and some can be recovered and reused as recycled plastic. In route 3 most of the plastic is used as fuel or reductant; very little is recovered as usable plastic.

After examining (a much more detailed version) of the information above regarding the environmental impact, we have concluded that route 2 (dismantling) is not only the best recycling scenario in terms of material recovery, it is also the best option in terms of environmental footprint. This is because it shows the best balance of energy creation and plastics recycling while minimizing CO2 emissions.

The benefits and limitations of modular design

After reviewing both material recovery and environmental aspects, our findings confirm that the modular design of the Fairphone 2 can be beneficial for recycling. Being able to dismantle the phone before recycling maximizes the recovery of metals, especially precious metals, plus maximizes the use of plastics for both material recovery and as an energy source.

However, modular design isn’t the definitive answer to optimal electronics recycling (yet). Besides potential benefits, there are also major product and industry-related challenges in design for recycling. Here are just a few examples:

- There is a (design/functionality) limit to how many modules you can put in one device.

- Design for recycling must consider the combinations of metals, compounds, fillers, plastics and functional materials to minimize the loss of elements. Complex combinations with many different materials existing in phones make this very challenging.

- Successful design for recycling needs to rely on simulations based on accessible, consistent data, which is currently often unavailable at an industry or supplier level.

For more information about the above points and what it means to design for recycling and resource efficiency, please read this report by Dr. Antoinette van Schaik (MARAS B.V.) and Prof. Dr. Dr. h.c. Markus A. Reuter (Freiberg, Germany).

Recycling and repairability go hand in hand

Based on the information above and what we shared in our previous blog post, we now know that 100% material recovery and circularity of a complex product like a smartphone will never be achievable. Even if recycling processes were perfect, the recovery of some materials will always inevitability result in the loss of others.

Urban mining workshop with the Fairphone community (Amsterdam, 2017)

We intend to keep striving to improve recycling, but understanding the limits of recycling has strengthened our conviction that repairability and lifetime extension are just as important when it comes to getting the maximum value from the materials used in our products. This approach is not yet mainstream, but we’re pleased that it’s starting to gain recognition. Last month, iFixit and Greenpeace published a product guide rating smartphones, tablets and laptops on their repairable design. We’re proud to share that the Fairphone 2 came out on top in the smartphone category.

It’s encouraging to see that topics like these starting to take root in the wider electronics industry. At the end of the day, real change in recycling and repairability will be driven by a joint effort from small players like Fairphone, major industry players, policy makers and you, the consumer.

Stay tuned for more blog posts in this series to learn more about what you can do to support and improve electronics recycling. Until then, please have a look our recycling program, especially if you have an old phone at home that can be reused or recycled.