How we got Fairtrade certified gold in the Fairphone 2 supply chain

Smartphones contain dozens of minerals sourced from every corner of the globe, including gold, which is commonly used in printed circuit boards (PCBs) as well as other wiring and components due to its excellent conductivity. And of course, it’s not only found in phones. Gold is an essential material in many of today’s consumer electronics, and the electronics industry is the third largest consumer of gold worldwide, after the jewelry industry and financial sector.

But the path that gold travels from the mine to your phone or other devices is often problematic, to put it mildly. To start, gold is one of the four conflict minerals identified by the Dodd-Frank Act. This means that gold has been known to finance rebel groups in the Democratic Republic of the Congo (DRC). Because tiny amounts of gold are extremely valuable, this mineral is also very prone to smuggling. Even outside of conflict and high-risk regions, gold mining poses a wide variety of social and environmental challenges, such as land disputes, sub-standard wages, unsafe working conditions, child labor and mercury pollution. However for many mining communities worldwide, it provides their main source of income and livelihood.

For all of these reasons and more, we are extremely pleased to announce that we have reached a major milestone: Together with our partners, we have achieved the first-ever Fairtrade gold supply chain for the consumer electronics industry! Keep reading to find out more about how we investigated and set up a pilot project to source Fairtrade gold and meet the other parties who were key to making our ambition a reality.

Together with our partners, we have achieved the first-ever Fairtrade gold supply chain for the consumer electronics industry!

Untangling the gold supply chain to find more responsible sources

From the beginning, Fairphone has been focused on mapping our supply chain, tracing the materials that are used in our phone and making improvements step-by-step. In terms of mining, our top priority is the four conflict minerals. With the first Fairphone, we identified (and continue to support) initiatives for sourcing conflict-free tin and tantalum. In parallel to developing the Fairphone 2, we turned our attention to tungsten and gold.

As soon as we started digging deeper into the gold supply chain, we realized that finding a fairer means of sourcing gold would be quite a challenge. To start, there were no existing supply chain initiatives that we could join to source conflict-free gold from the DRC – and setting up one from scratch was simply beyond our scope. However, there was one responsible mining initiative that we could possibly connect to the Fairphone supply chain: Fairtrade certified gold. While it’s not sourced from a conflict area, what’s especially attractive about Fairtrade is the amount of emphasis put on improving working conditions and providing direct developmental impact for artisanal miners.

Fairtrade certified gold is now part of the Fairphone 2 supply chain

With our goal clearly in mind, we were determined to set up a pilot project to support Fairtrade gold mining with the Fairphone 2. And after nearly two years we’re finally there! It’s been a challenging road to say the least, and it wouldn’t have been possible without the help and support of a wide variety of partners.

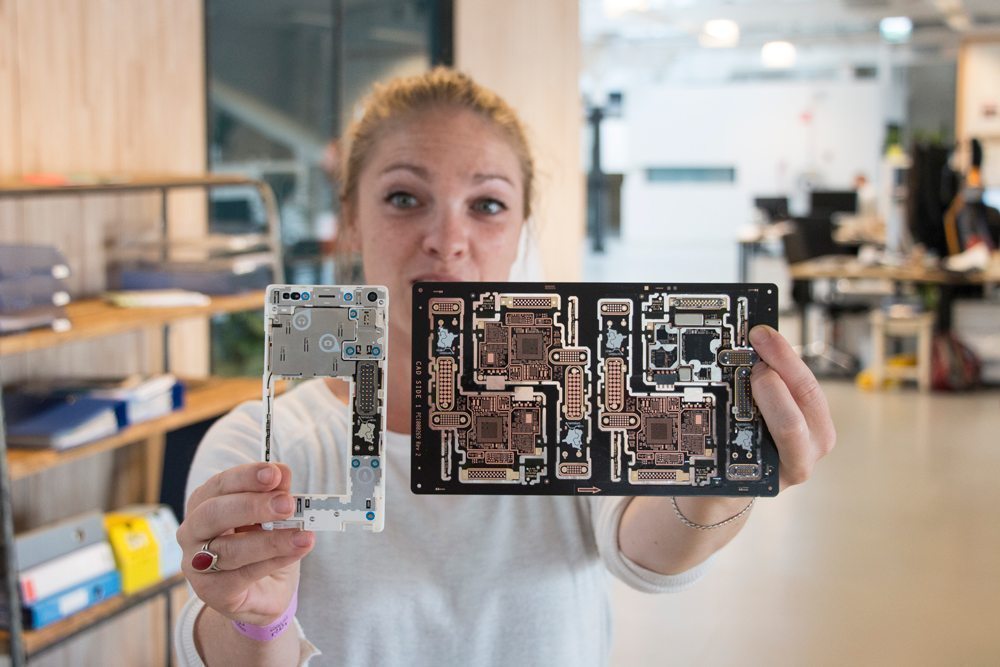

Our quest to source Fairtrade gold started by gaining an understanding of where gold comes from and where it ends up in our phones. (For additional information on what we discovered about the gold supply chain, have a look at our recent blog and video of the research trip to China with our partner AT&S)

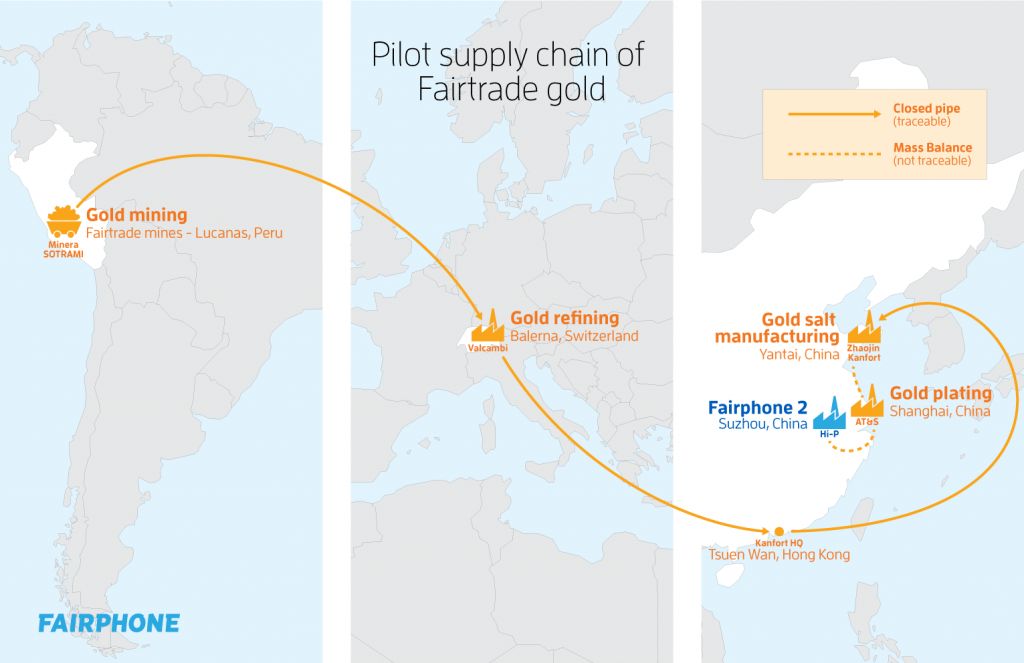

The gold found on the PCBs is applied using an electroplating process, which means that AT&S dips parts of the PCBs into a liquid solution that contains gold. The gold in this solution comes from adding grains of gold salt – so the next step back in the chain was connecting with the supplier of gold salt: Zhaojin Kanfort. After hitting a dead end with our earlier attempts to trace Fairtrade gold into China (because all of the country’s gold is traded through the Shanghai Gold exchange), Zhaojin Kanfort was able to provide us with a solution. In short, they are able to import Fairtrade certified gold through their head office in Hong Kong and then trace it to their gold salt manufacturing facility in Yantai, China.

From Peru to Switzerland to Hong Kong to China: the journey of Fairtrade gold

Throughout this entire pilot, we have been in touch with Max Havelaar in the Netherlands to help us facilitate the process. We will be sourcing gold from MINERA SOTRAMI S.A. (Sociedad de Trabajadores Mineros S.A.) in Peru. MINERA SOTRAMI has 164 shareholders and employs 260 mineworkers as well as five engineers who manage the mine and processing plant. The gold mined here meets the Fairtrade Standard for Gold and Precious Metals, meaning that rigorous social, economic and environmental regulations are followed including child protection policies. In addition, the miners are guaranteed a Fairtrade Minimum Price and Premium that assists in sustainable development for the community. This way, the mine supports 500 families.

A positive step, but challenges remain

The Fairtrade certified gold arrived safely in Hong Kong on the 25th of January 2016. By establishing this pilot program, we are now the very first Fairtrade-licensed consumer electronics company. Although the gold is not traceable to the specific batch of gold salt for AT&S, it is the first time gold can be physically traced to our sub-supplier in China to produce gold salt. So, if you decide to buy a Fairphone 2, you can be certain that you’re supporting Fairtrade gold miners and their communities in Peru.

Fairphone 2 owners are supporting Fairtrade gold miners and their communities in Peru.

For us, this entire process has reiterated the importance of building close relationships with our suppliers to better understand our supply chain and have the ability to influence materials sourcing. By sourcing Fairtrade certified gold, we hope to demonstrate to the rest of the industry that it’s possible to open up, map your supply chain and support responsible mining initiatives.

While we’re proud of what we’ve achieved, it’s important to point out that this is a pilot project which only requires a small amount of gold. Realistically, scaling up the Fairtrade gold supply chain for the consumer electronics sector will require new pricing structures, licensing and logistics as well as demand from manufacturers much larger than ourselves. We certainly can’t do it all on our own, but by finding the right partners and making consumers more aware of the issues, we’re moving in the right direction.

Header image credit: Sean Hawkey