Guest Blog: Fair Cables for Fair Electronics

Editor’s Note: This week we have a post from Susanne Jordan of NagerIT, where they have done tremendous work investigating the sourcing of fair electronics. All statements and opinions are author’s own.

Before I start writing about fair cables, I should introduce my organization: NagerIT is a private initiative (non-profit), and currently there are seven of us involved.

Similar to Fairphone, NagerIT is working on an ethical improvement of the production process of our electronic gadgets. We started developing a fair mouse in 2009, which can be purchased from last December. We are aware that sustainability is more than labor rights (the mouse has a biological cover, is easy to repair, spare parts are available, and so on), but nonetheless we put special focus on the working conditions in the production process, that is all factories and mines involved. Why? After doing some years of research on sustainability in the IT sector, we found that all major IT-companies (which we want to challenge) successfully have excluded this topic from their CSR efforts despite all qualified critics of many NGOs regarding human rights violations in the supply chain. The brands keep on saying that this issue is a structural problem and cannot be solved by them. However, we think something has to be done to protect the human rights of the workers. This is why we strongly focus on a fair supply chain in order to prove that it indeed is possible – if we are willing.

So, how can we make sure, our supply chain is clean (of human rights violations and major environmental destruction)? The first step towards fair working conditions inevitably has to be transparency.

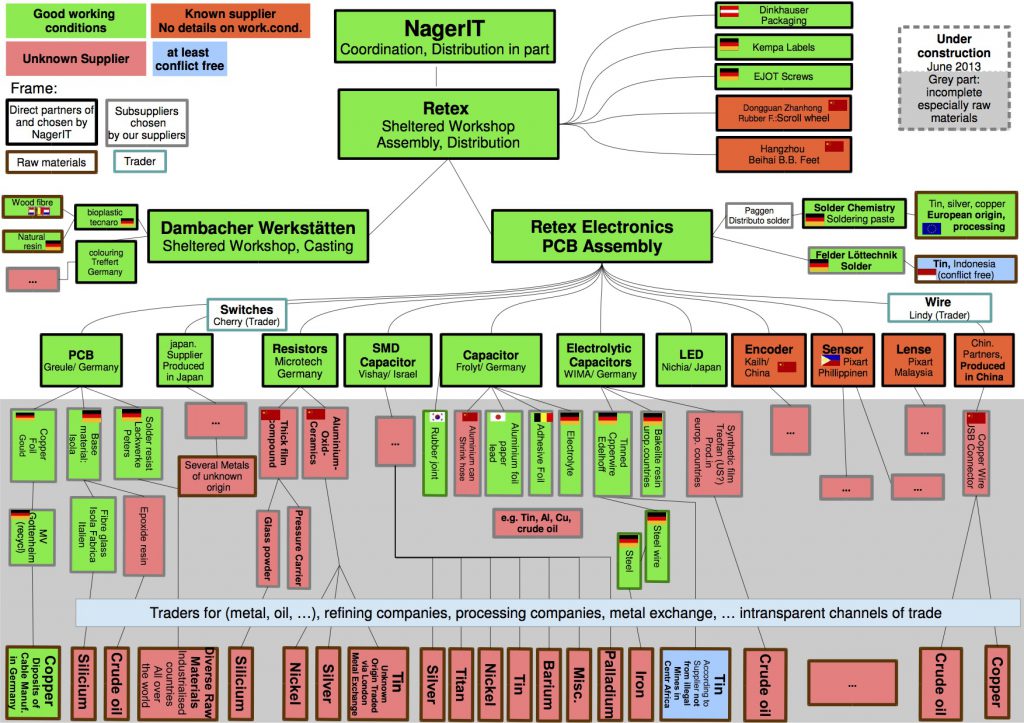

And this is, especially for small projects like Fairphone and NagerIT, a major challenge. You can see how far we’ve got, after 4 years of intensive research, in our supply chain.

This is an overview of the current supply chain of our mouse. But of course, this can not be the final structure. Our aim is to make the whole production process transparent and green, that means no exploitation. To manage this “half-fair” mouse was quite an effort. However, I have the feeling that the major challenge still lies ahead. I would like to explain the challenge using the example of the USB cable.

Transparency in the Supply Chain

What is the problem with the USB cable so far? Our current cable (sourced via Lindy, a German trader) is produced by a company called Chang Rong Chang Electronics, producing in Shenzhen, China. Shenzhen is a region near Hong Kong, where a bulk production of IT equipment takes place. The region is known for extremely poor working conditions. At least our cable is PVC-free, which means it causes less health and environmental (especially climate) problems, especially during disposal. However, as mentioned before, the focus of NagerIT lies on the situation of the workers involved in the production process, and hence PVC-free is not sufficient for us. Therefore we started cooperation with our trader (Lindy, Germany) to find a more suitable factory with good conditions for the workers. In autumn we are planning to jointly visit some partner factories of Lindy in the Ningbo region. Ningbo is a region near Shanghai, where on average, working conditions are better than in Shenzhen.

Once a suitable factory has been found, we have to start long and patient talks in order to convince the owner of our project: the factory should report transparently on its working conditions and, very important and very challenging, their supply chain. If necessary, conditions of workers have to be improved. A big challenge will be to encourage them to disclose their supply chain to us. In the IT sector, and especially in China, a company’s major asset or competitive advantage seems to lie in their knowledge of sourcing opportunities.

Keeping in mind the extreme competition in this sector, one can understand concerns about transparency. However, we have to insist on that, otherwise how can we check and, if necessary, improve the situation of the workers in the factories and mines that are supplying to them? Providing transparency is not sufficient to call something “fair,” but it is definitely an essential step. So please keep fingers crossed that we are successful in this challenging problem.

After having gained transparency, we will have to find a reliable partner to audit the factory during the production process. But it’s not only that company that has to be monitored. Please have a look at our picture of a dismantled, open cable.

All single parts are produced in certain factories which we need to check. These factories are again supplied with raw materials, eg. copper and tin, the origin of which we need to find out before we can check conditions there.

That is for the cable. We will repeat this process for all components we use, one by one, further down the supply chain. However, we know the way to perfection is always long, so we can enjoy every single step on this journey!

Future Collaborations

Why do I write all of this on the blog of Fairphone? Simple answer: There is a shortcut toward fairly produced electronics, we can work together and use synergy. Not only Fairphone and NagerIT, but all future fair electronics projects will need common components like cables, resistors, capacitors, and the like. This means that once suitable suppliers for, e.g. USB cables is found, this source can be used by all interested companies and projects. The challenges only need to be solved once, and then we can reach our goal double speed! The next project of NagerIT is a fair cable usable for NagerIT, as well as for Fairphone and others. In the future, perhaps Fairphone will find a type of resistor with conflict-free tin, or other fairly produced parts that NagerIT can use as well. Let’s find out!

Photos provided by NagerIT