Editor’s Note: In this blog post, Mulan has put together a collection of photos with Miquel and Bibi, to document the final stages of production. Here we’ll outline 1) the pre-assembly period, 2) putting all the components and materials together on to the final phone. The last step of packaging the phones and following their journey from Chongqing will be posted in the next few days.

Times are busy here in Chongqing prior to Christmas and the very first Fairphone delivery! We know you can’t wait to see your phones in real life, so here’s a few production pictures from the last few weeks at the factory. Miquel visited for two weeks, and Bibi is currently here. Together we’ve put together this photo blog documenting the last stages of production. Take a look!

![Yuan Ride]()

Our daily commute from the center of Chongqing to the factory for two Chinese yuan. Pretty smooth except for the occasional traffic jam.

![Wilson Mulan]()

Here I am talking to the guys from Process Quality. Together, we monitor our production so that everything runs as smoothly as possible.

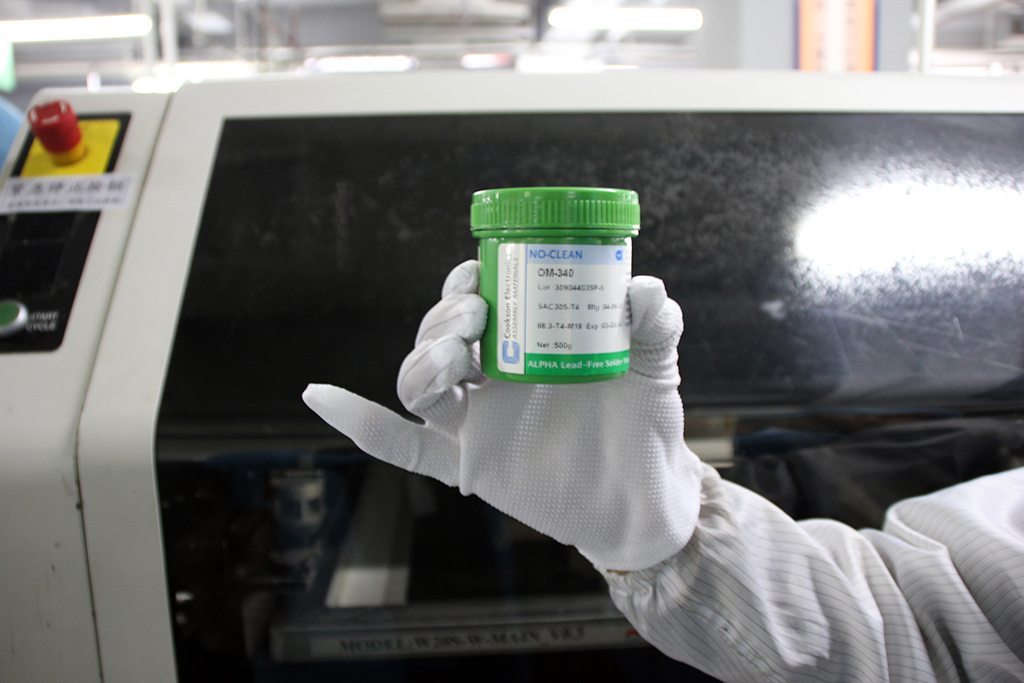

![Soldering Paste]()

The components get soldered on the circuit boards using soldering paste. This one contains tin, which was sourced through the conflict-free tin initiative.

![SMT Machine]()

This is the pick and place machine which places the components on to the printed circuit board of your phone.

![Component Rolls]()

… dozens of spools are used. One of them contains capacitors with tantalum from the Democratic Republic of Congo, sourced through the Solutions for Hope project.

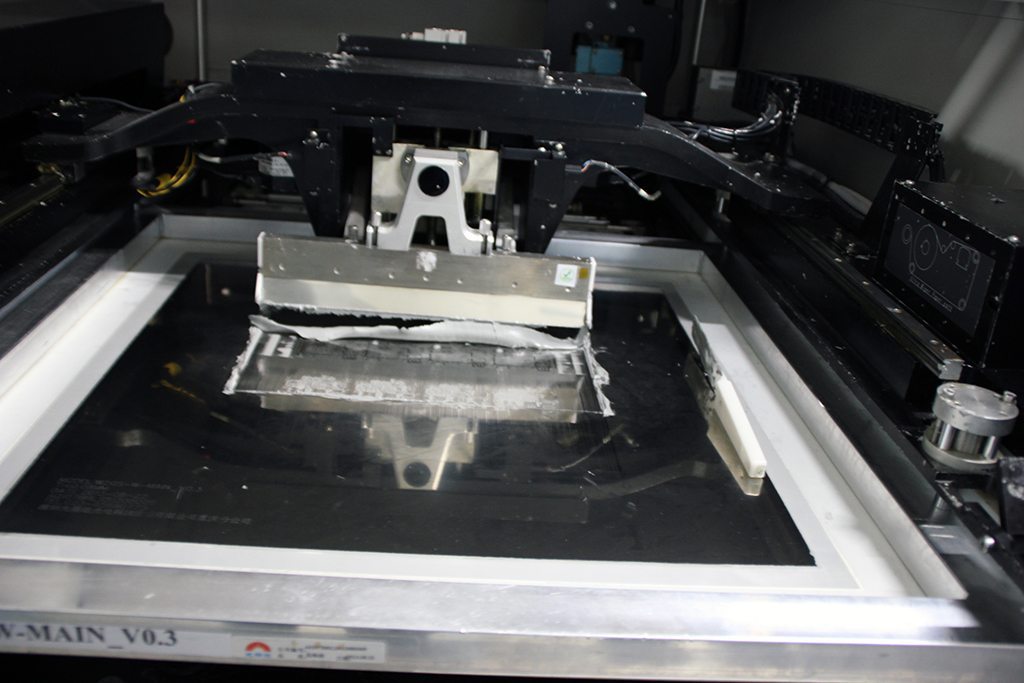

![Peanut Butter Paste]()

This machine applies soldering paste by swiping many printed circuit boards at the same time.

![Prod Line]()

View from the beginning of one of two Fairphone assembly lines.

![Fairphone Brains]()

Here the printed circuit boards are ready to be put in to place.

![Soldering]()

Here’s tin in the shape of soldering wire.

![Beatles]()

They are everywhere.

![Prod Line Screw]()

Screwing things up.

![Quality Control]()

Quality Control happens at the end of the assembly line. The people here have well-trained eyes.

![Flash Memory]()

Testing the cameras on the phone after which storage is erased.

![Test Call]()

Using fancy test equipment to calibrate the radios.

![Mulan Office]()

This is where I sit when I work at the factory. I’m in the same office as the team of engineers, project managers and other people responsible for the Fairphone production.

![Bibi Office]()

Another visitor this week as Bibi visits Chongqing in the framework of our “Made with Care” program – and gets a desk next to mine.

![All Office]()

f.l.t.r. Team meeting with people from Process Quality, Project Management, Structural Engineering, Stella (Fairphone’s project manager) and myself.

![New Years Dance]()

Not all work at the factory. Here some workers are practicing the team dance for their Chinese New Year party.

![Bibi Mulan]()

After a day’s work, we take the bus back to the city.

![Chongqing Night]()

And I leave you with a nice landscape view of Chongqing by night.

Greetings from Chongqing! Happy holidays, safe travels everyone. More news after the weekend!