We like to make things difficult: How your Fairphone is made

Your phone isn’t born in a store – that shouldn’t come as a big surprise! But what happens before you bring home your shiny new device? Today’s smartphones are essentially mini computers made up of hundreds of parts, so the steps that go into making them form quite a tangled web.

Manufacturing “regular” phones is already difficult enough, but at Fairphone, the way we do things adds an extra layer of complexity. That’s because we’re working to make phones fairer at every step in the process, from the materials we use and the way the workers are treated, to how the phone is designed. And to make things even more challenging, some of our ideas are very new for our industry, so we’re often exploring uncharted territory and setting up programs and procedures completely from scratch.

To give you a better idea of how it all works, let’s take a backwards stroll through how your phone is made. Along the way, we’ll point out how Fairphone is doing things differently at some of the most important points in the process.

Final assembly

The regular way

Before a phone ends up in a box in your hands, someone has to set up the assembly line, put hundreds of pieces together, plus inspect it and test it. For most phone manufacturers, that “someone” is a final assembly partner, often located in Asia – the heart of the electronics industry. These factories can turn exciting new product ideas into reality, and can take care of all the tiny details related to assembly, so their clients don’t need to worry about it.

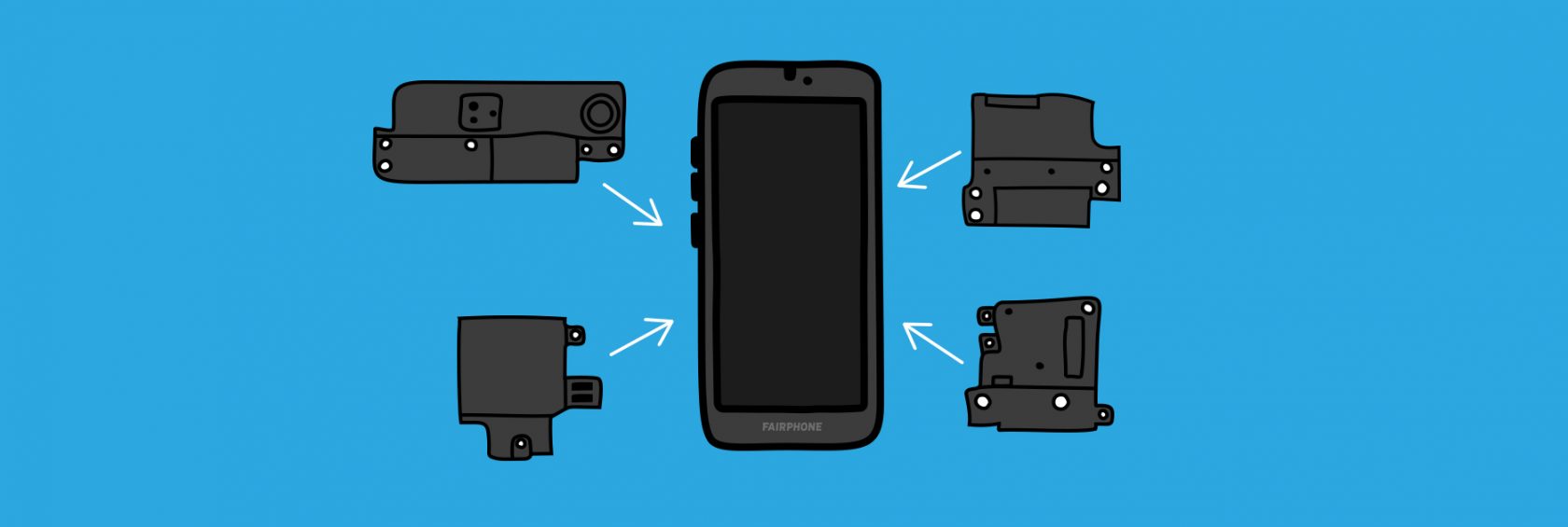

The Fairphone way

At Fairphone, we also work with a final assembly partner – for the Fairphone 3, it’s Arima. However, we prefer to be very hands on with the smaller details. For example, we often want to work with specific component suppliers or request additional information about where the parts come from. We also collaborate with our assembly partner to create better, safer working conditions (and sometimes special bonuses) for their employees.

Components

The regular way

Phones are made up of a gazillion (okay, maybe a thousand) tiny pieces and parts that need to be ordered, assembled, screwed and soldered together. Smartphones contain a lot of the same components – like the processor and camera – but depending on the model, there are different technical specifications (like the amount of memory, megapixels, etc.). Often, the assembly partner decides which suppliers to use for all these parts.

The Fairphone way

While we definitely leave some of the decisions to our partners, we’re also very picky about working with certain component suppliers. Because of our fair ambitions, we’re partnering with a small selection of companies to set up improvement programs and get responsible materials into their products. We also have some tricky design requirements, because the parts we use need to be suitable for our modular, repairable phone.

Materials

The regular way

Phones contain dozens of different materials – from glues and plastics to copper and gold. While there are some regulations in place about the type of materials used and where they come from, most manufacturers think about materials in terms of properties and performance, and worry less about their origins.

The Fairphone way

Fairphone was founded because of our obsession with materials. Because it can be hard to know where these metals and minerals come from (and who is mining them), we’re finding and/or building more responsible material supply chains that are better for people and the planet. So far, we’ve managed to get better sources of tin, tantalum, tungsten, gold, copper and plastic into our phones.

Want to know more?

This is just a brief introduction to how we do things differently to make phones fairer. It’s not always quick, and it’s certainly not easy, but with every positive change we make, we’re getting one step closer to our vision of fair electronics. If you’re curious to find out more, read more on how we’re making an impact or get in touch on Facebook, Instagram or Twitter with all your burning questions.