December production update: How production, workforce and delivery are intertwined

As Value Chain Director, I work to increase positive social and environmental impact throughout our product’s value chain, and that’s a pretty long chain, starting with mineral sourcing, and extending through manufacturing, design and life cycle. As I’m a recent addition to the team, I’ve immediately started working with the product and operations teams to look at production issues while maintaining Fairphone’s social values. This blog post focuses on the manufacturing part of our value chain where I’ll outline our current production status and explain how production, workforce and delivery are intertwined.

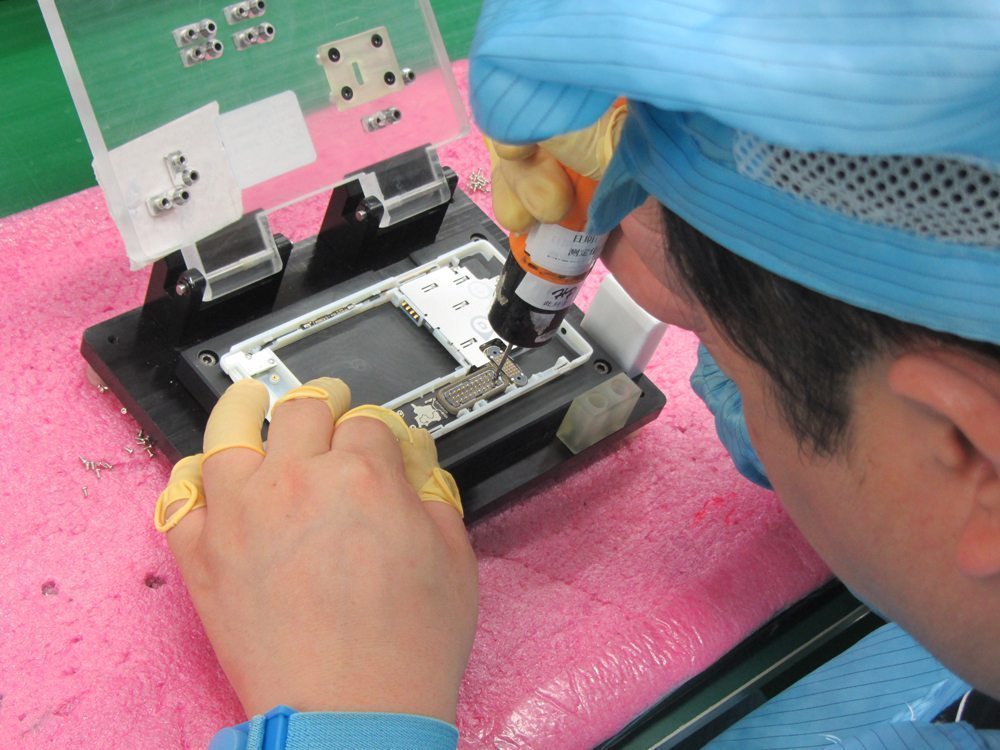

In the past weeks, the Fairphone team has been working very closely with our manufacturer, Hi-P, to resolve the last steps to reach final production and deliver the first batch of Fairphone 2’s to customers.

Based on our production planning, the first phones will be shipped from our new distribution partner, Rhenus Contract Logistics, in the Netherlands starting the week of 21 December. We estimate that up to 4,000 phones will be shipped before Christmas, and another 6,000 phones are expected to leave by the end of the year. Based on our current sales, the remainder of the pre-ordered phones will be shipped during the first half January. After which we will start building inventory.

*Edited on 15 Dec: The latest information about production and shipment numbers can be found in this blog.

In our current planning, the first phones will be shipped across Europe starting the week of 21 December. We estimate that up to 4,000 phones will be shipped before Christmas, and another 6,000 phones will ship by the end of the year.

We’re sorry to say that the quantities we’ll ship during December have fallen below the 15,000 originally planned, and realize that some of you may have to wait longer than you hoped, especially if this was a holiday present. (And we’re even working on a special holiday while-you-wait phone for those who want something under the tree.)

However, we’d like to use this opportunity to give you more insight into what’s happening behind the scenes and the various factors that come into play when making decisions about production.

Shipping delays but now we’re nearing final assembly

Although we’ve had a few setbacks that have caused shipping delays, we’re nearing final assembly. As we wrote in our production update at the end of October, some last-minute changes required us to reorder custom parts. Unfortunately after that, we were delayed again with a component issue which required it to be remade by the supplier. This sometimes is a part of the manufacturing process, but it’s unfortunate timing just before ramp-up of final assembly. Now that we have validated the component, this week we are completing the final controlled ramp-up build. If this goes well, next week final assembly will begin.

Consistent sourcing of materials for production is a frequent challenge in our industry. Materials come from hundreds of suppliers spread across the globe, which makes the end of the production chain vulnerable to become a bottleneck for any quality issues or delays that may arise and have an impact on the rest of production. In managing these issues, we’re also taking into account the impact this will have on the workers needed to carry out production.

Balancing workforce and production requirements

When we’re facing a delay like this, how can we move forward to get the phones to their owners as fast as possible? And what are all the different factors we need to take into consideration?

The production and assembly of the Fairphone 2 is not done in isolation – it’s closely linked to working conditions for the factory employees as well as the production demands we place on our manufacturing partner. The Fairphone value chain, operations and product teams have been closely collaborating with Hi-P’s management to find a balance between our production requirements and the related workforce requirements.

Our ultimate goal is to encourage a stable environment for Hi-P’s workforce. We want our production needs to support – and not hamper – that. So wherever possible, we encourage a hiring policy that enables a more stable workforce, higher job security and stronger employee engagement, resulting in benefits for both workers and the company.

A strong employee engagement is an important condition for the success of the impact programs we are implementing with Hi-P, which includes building trust and dialogue between workers and management. Beyond that, we believe that it will reduce workers’ turnover, therefore reducing costs in recruitment and training. More experienced workers on the production line also increase efficiency by lowering the risk of needing to rework parts.

Just to reiterate, the primary reason behind our delivery delay isn’t the (availability of) workers – it’s because of production issues. But to compensate for these delays, it’s a known industry practice for manufacturers to look for ways to speed up production, relying on excessive overtime work or hire workers on a short-term basis.

Fairphone and Hi-P’s plan to create a stable workforce

Together with Hi-P, we have developed a plan that matches our production volume forecasting and our long-term ambitions to ensure a stable workforce. This was a tough decision as we know we have Fairphone 2 buyers who are patiently waiting. That’s why it’s so important to have steady sales and a good forecasting model to achieve this goal going forward. Proper planning and relying on pre-orders is a challenge for a growing company, and we want to thank all our supporters who have already pre-ordered a phone and helped us set our goals in motion.

In the next weeks, the ramp-up of Fairphone 2 will mean many workers will be needed to complete production. In order to meet the original production demand in a shorter period of time because of this above-mentioned delay, a large amount of short-term contract workers would have been needed to meet our order. However, we felt this was not consistent with our goals. Therefore, Fairphone and Hi-P made a plan to work towards a more stable workforce through Hi-P’s hiring practices: avoiding short-term contracting and hiring employees with an offer of direct-hire in the coming three months.

Fairphone and Hi-P made a plan to work towards a more stable workforce through Hi-P’s hiring practices: avoiding short-term contracting and hiring employees with an offer of direct-hire in the coming three months.

Our work on matching production volumes and required workforce is an ongoing process, but we believe this is a big step in our collaboration with Hi-P in aligning business and social values.

Next steps before delivery

Even though we know you’re counting down the days to delivery (we are, too – we can’t wait!), we know you understand these issues are at the core of what we do. We want to support practices we all stand for as a company and community, and now we ask for your patience just a little longer.

Keep checking our blog (and your Inbox) for more news about final production and assembly next week. We’re almost there!