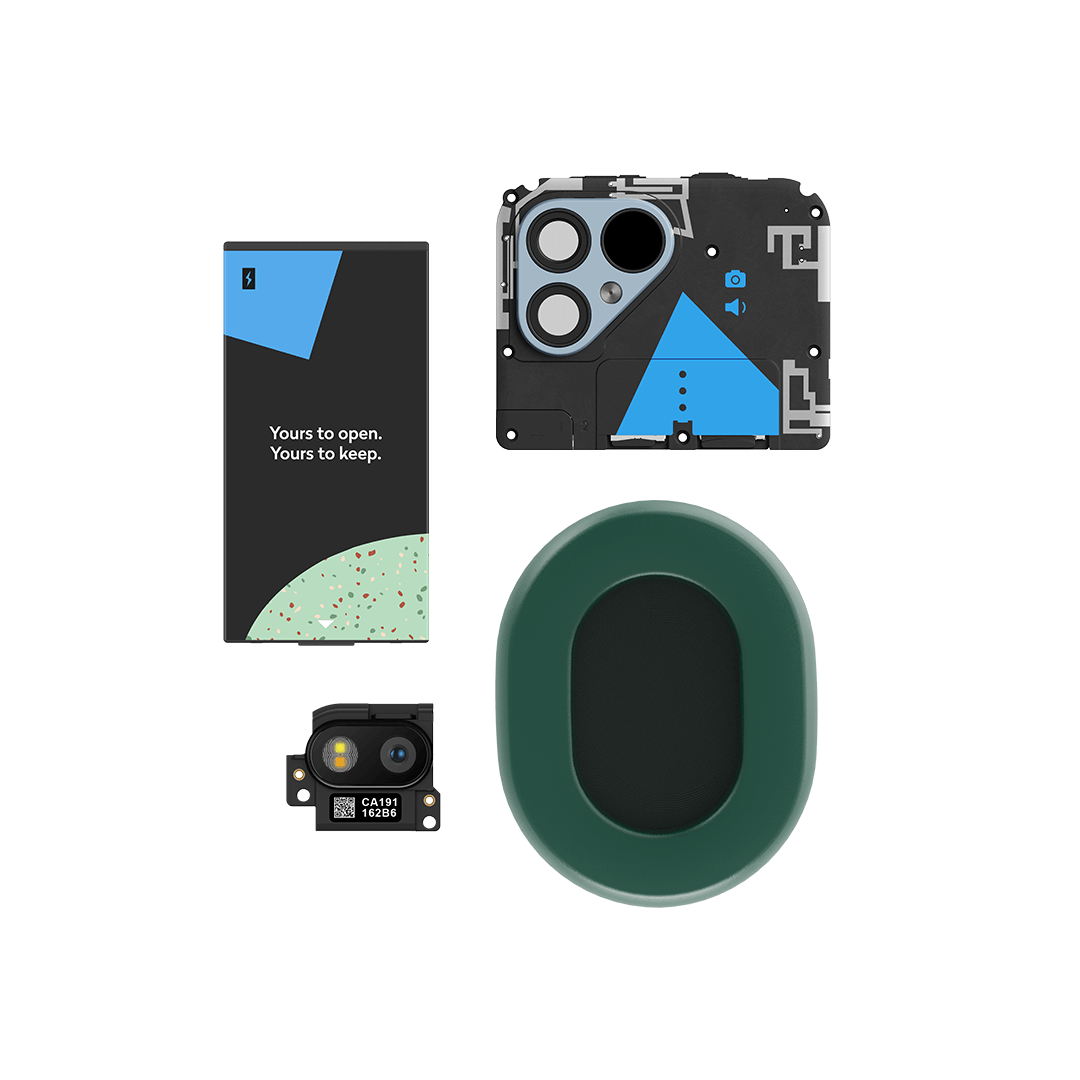

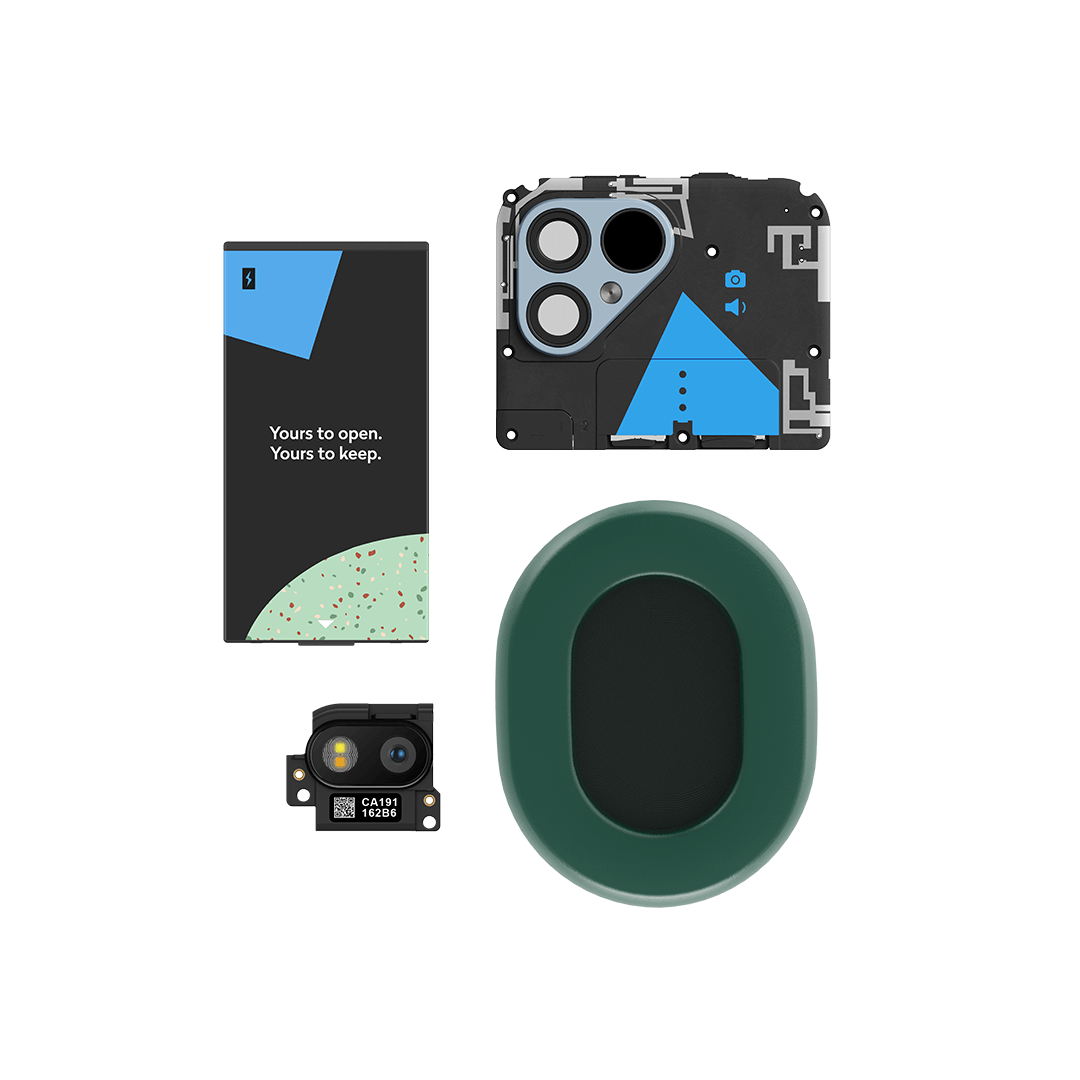

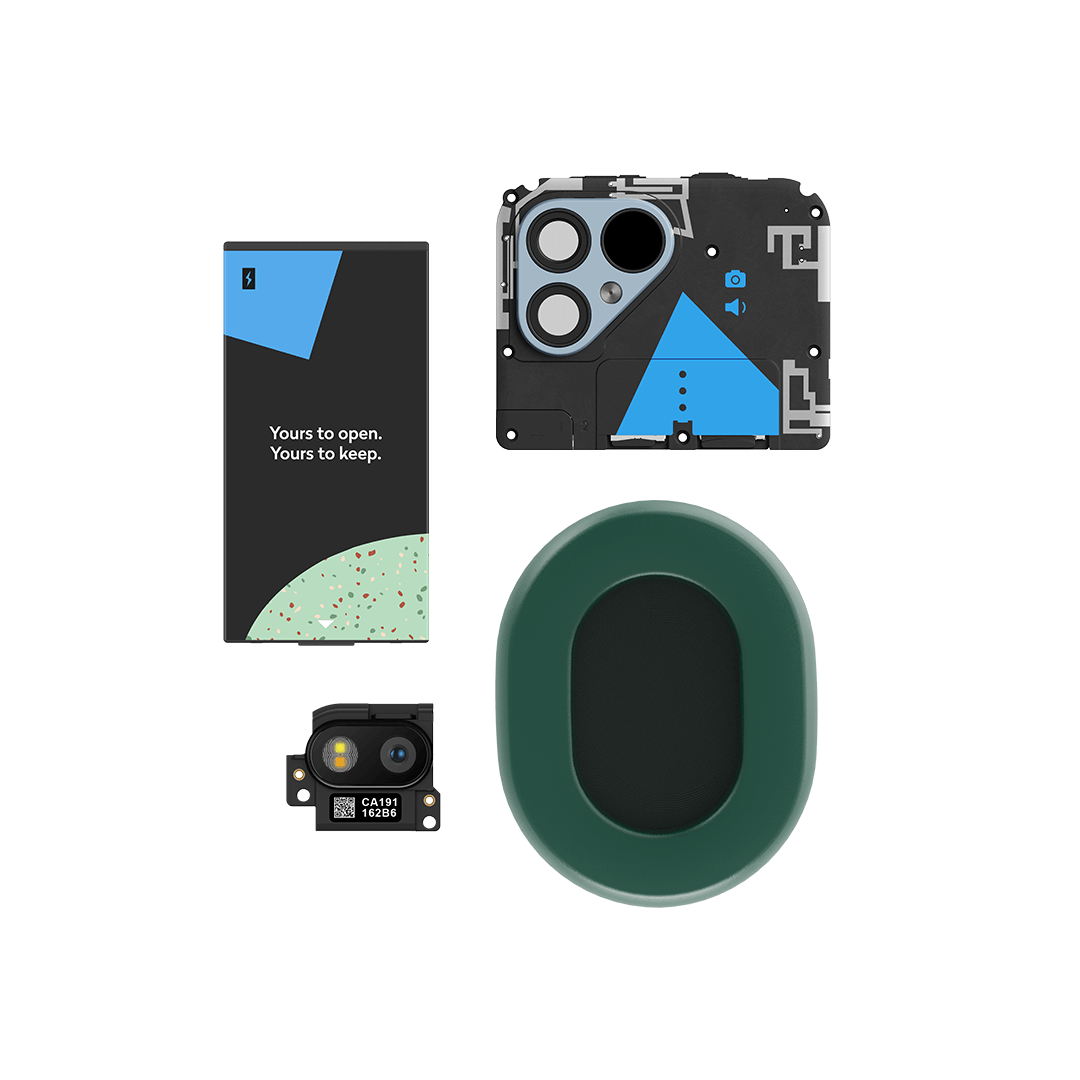

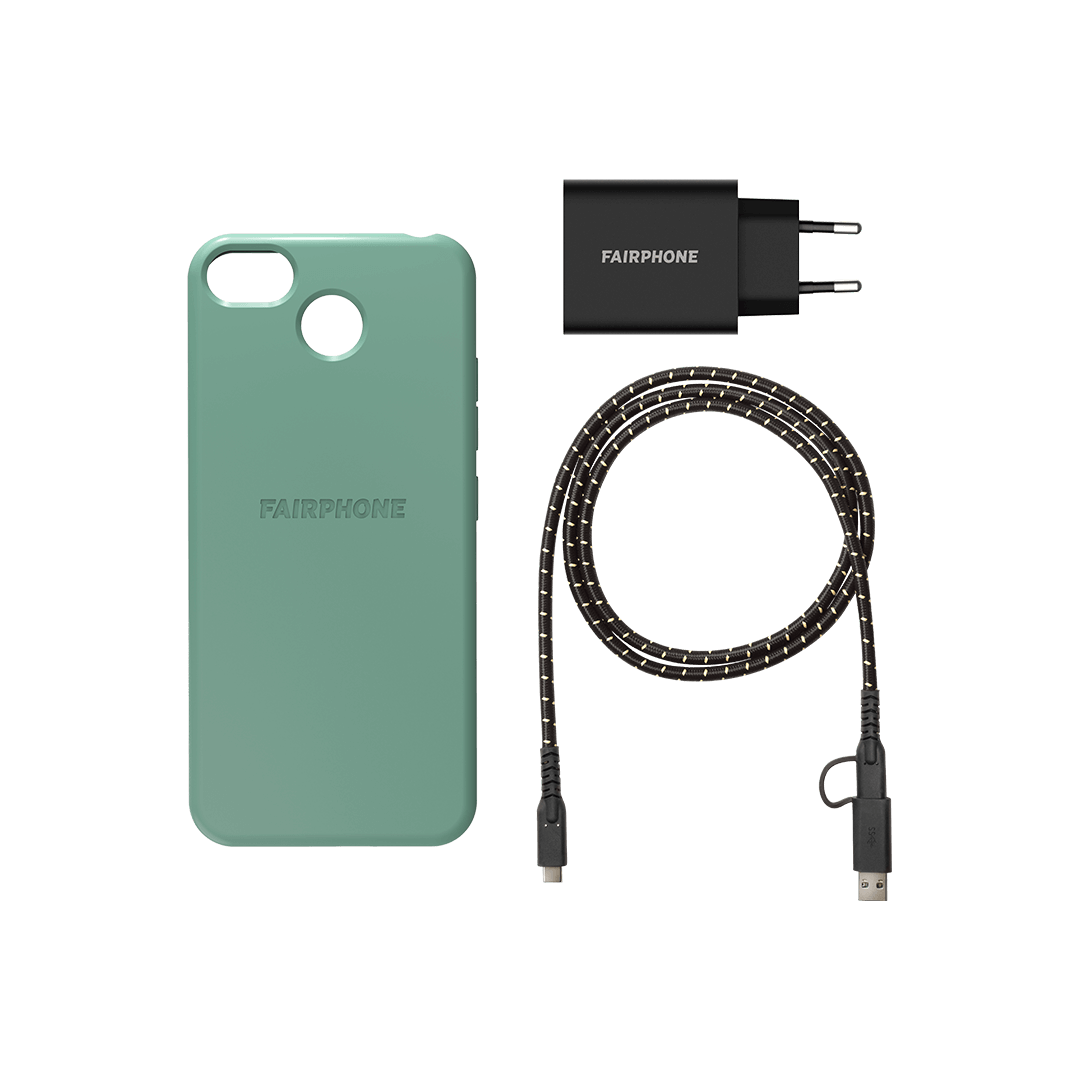

SPARE PARTS

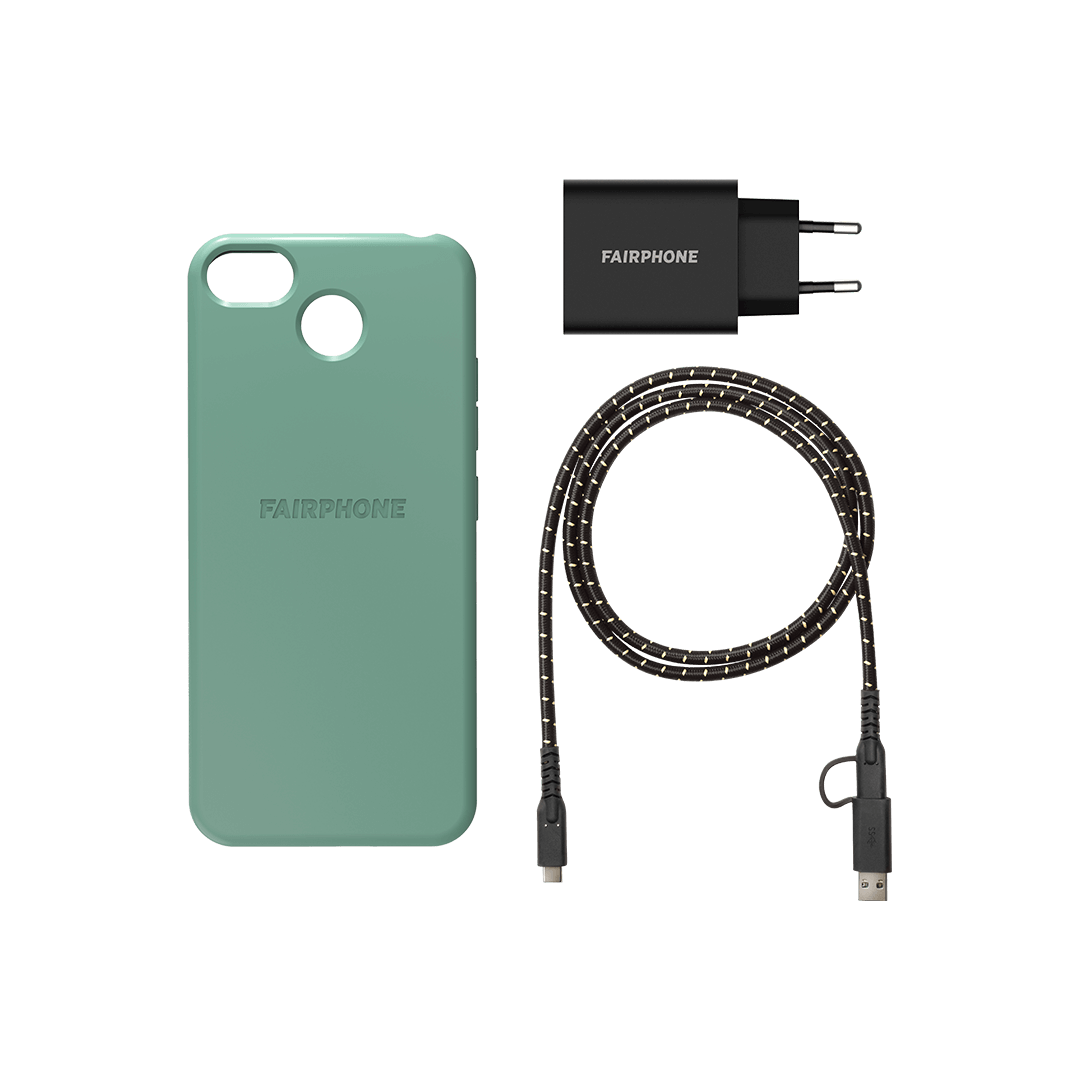

The best deal for you and the planet: Buy the Fairphone 4 , get a free case and screen protector.

We make fair(er) phones - To change the industry from the inside. One step at a time, all over the world. Together with our community, we’re changing the way products are made. Here's how we're disrupting the tech space.

About us

The most sustainable phone is the one you keep. With industry leading hardware warranties and software-support, Fairphones are designed to grow with you.

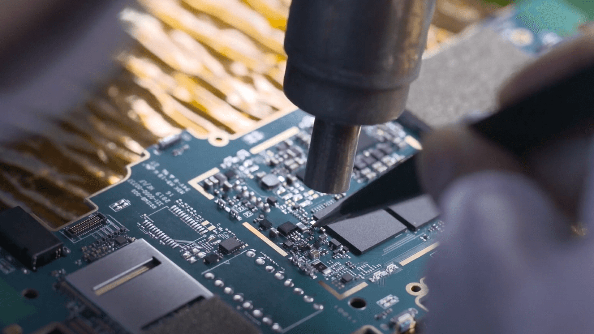

How your phone is made matters. Each Fairphone is made with fairer, recycled, and responsibly mined materials.

We’re avoiding and reducing carbon emissions by designing our phones to last, using recycled materials, powering factories with 100% renewable energy and investing in projects reducing CO2 emissions.

With each phone, we’re moving closer to a world where the makers are treated fairly, paid well and take pride in what they do.

Do you have an old phone lying in a drawer somewhere? Why not reduce the waste? It’s worth it.

RECYCLE YOUR PHONE

With this immersive documentary we're exposing the reality of the smartphone industry.

Read more

That’s what iFixit founder and CEO Kyle Wiens thinks after tracking Fairphone’s journey over the last ten years.

Read more

Apple’s new head of hardware, John Ternus, was asked whether iPhones could ever be as easy to repair as Fairphones.

Read moreGet early access to our latest stories, exclusive deals and opportunities for change.

Didn't receive the email? Please check your spam folder.

There are more phones than people. And behind every device is a complex supply chain. With suppliers, local communities and the wider industry, we work for fairer materials and more responsible practices. Showing the electronics industry that we can do better.

Together we’re disrupting the industry’s short-term thinking that the world can no longer afford. And changing what it means to be “best.”