Supporting fairer mineral initiatives with the Fairphone 2

Before we produced a single smartphone, Fairphone started as a campaign to increase awareness of conflict minerals in consumer electronics. We now focus on creating a positive impact in a wider range of areas in our value chain, but the topic of conflict minerals remains close to our hearts.

Over the past couple of years, we’ve written extensively about conflict minerals (tin, tungsten, tantalum and gold) and related legislation in the US and Europe. We have also shared our story about sourcing and integrating conflict-free tin and tantalum into our supply chain for the first Fairphone. Our most recent updates included a research trip to mines in Africa and an explanation of how we’re working to find fairer sources of gold.

But there is more to tell! While our technical and design teams have been busy developing the Fairphone 2, the value chain team has been working on an evolving strategy for supporting conflict-free tin and tantalum, as well as making a serious effort to incorporate fairer tungsten and gold into our latest phone.

Traceability: Knowing where our minerals come from

Recent industry and legislative developments related to conflict minerals focus on transparency and disclosure. Per the Dodd-Frank Act, companies listed on the US stock exchange must report if their products contain conflict minerals sourced from the Democratic Republic of the Congo (DRC) and surrounding countries.

To understand whether or not a product contains conflict minerals, you first need to know where the minerals come from. This is referred to as traceability, which is the process of following a mineral’s path from raw material extraction to the final component or consumer product. But it’s not just about identifying a mineral’s origins. Because traceability models track a material’s transformation and handling throughout every step of the supply chain, they are also very useful for ensuring the validity of various claims, from sustainability and environmental protection to improvements in human rights and working conditions.

Our goal is to integrate minerals into the Fairphone supply chain from responsible initiatives, and traceability is one of the tools we can use to achieve this. We want to ensure positive impact at the local level – for example, we prefer to source minerals from conflict-free validated sources in areas that are facing a high risk of conflict, like the DRC to stimulate the economy there. Ideally, we want to know what percentage of the material sourced from a specific initiative is incorporated in our end product. Finally, we want to ensure that our sourcing channels are economically sustainable, scalable and have the potential to be used or copied by other electronics manufacturers.

A mass balance model for conflict-free tin and tantalum

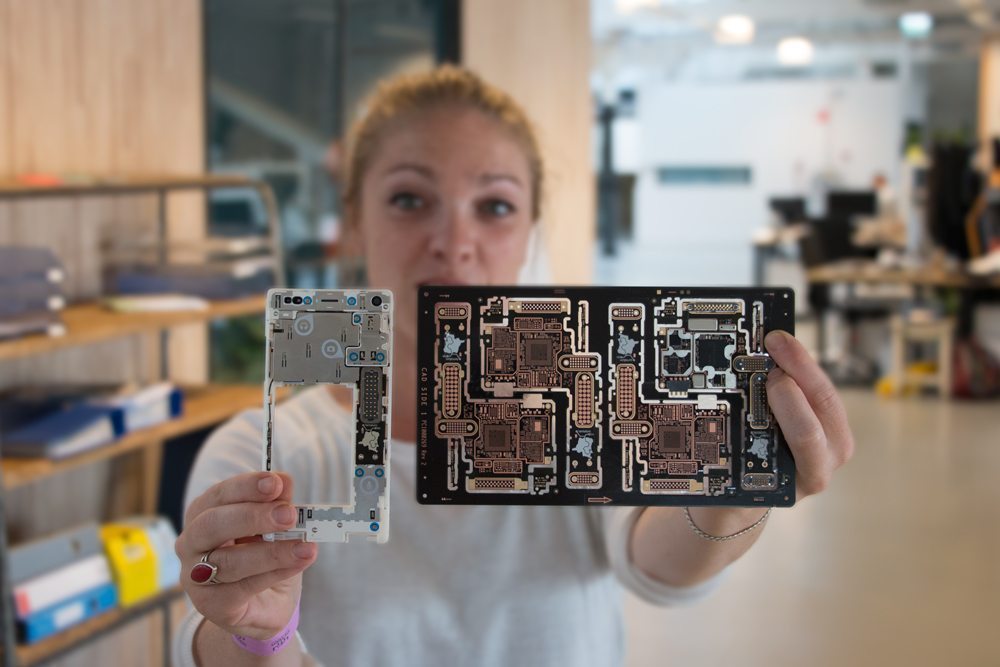

The first Fairphone contained conflict-free tin and tantalum sourced from the DRC in collaboration with the Conflict Free Tin Initiative (CFTI) and Solutions for Hope, respectively. In the Fairphone 1, the conflict-free tin was used in the soldering paste and conflict-free tantalum was used in capacitors on the printed circuit boards.

When we started working together, the CFTI was using a product segregation model of traceability. This means that the conflict-free tin was physically separated at every stage of the supply chain, from the mines and smelters to production lines. A product segregation model is very attractive in terms of traceability, as it allows you to follow the movement of a specific mineral all the way up the supply chain and understand exactly how much of that material ends up in the final product, in our case, a phone. This model works especially well for products that undergo very few transformations along the supply chain – think of a fair trade banana, for example. However, for long and complex supply chains like those for consumer electronics, this model is not always feasible.

Therefore, over the course of the two-year CFTI project (a pilot sponsored by the Dutch Ministry of Foreign Affairs), they made a strategic move from a product segregation to a mass balance traceability model. With this model, certified and non-certified materials can be mixed. (For additional information about traceability and related models, you can read this detailed report published by the United Nations Global Compact.) In addition, in 2014 the CFTI project evolved into a new project entitled “Scaling Up Mineral Trade”.

The decision to move towards a mass balance model came with the realization that product segregation was not economically sustainable, as it added expenses at every step in the supply chain. Employing a mass balance model reduces costs while expanding the reach of the project. It increases the number of conflict-free mines involved in the system, creates a more dependable flow of materials and provides more consistent quality. An open market system is also much more scalable than a closed loop with a limited number of predefined players and gives artisanal miners access to more legitimate buyers to sell their material to.

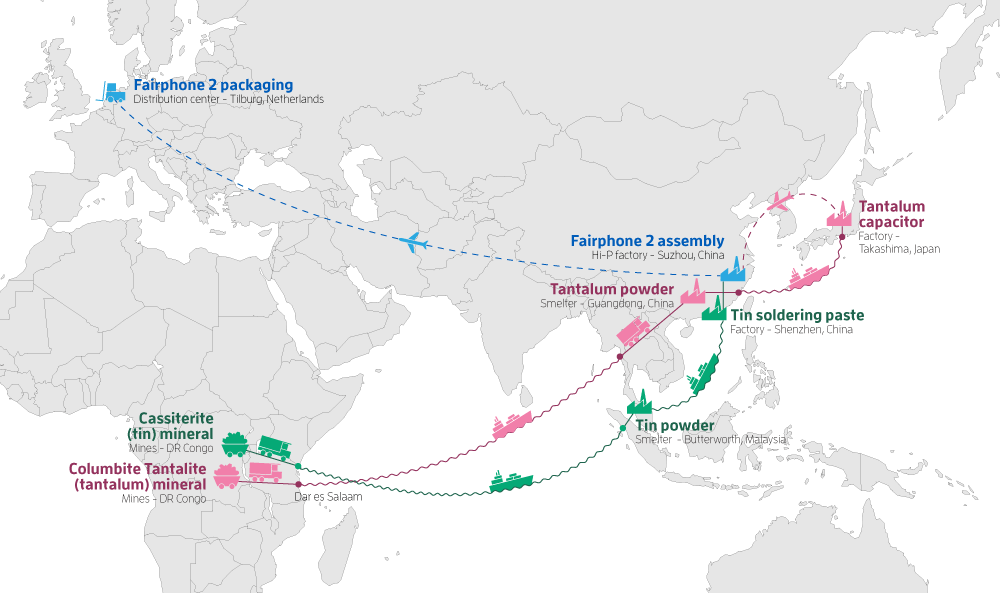

Practically speaking, the move to a mass balance model means that we source through smelters that are processing ore from the conflict-free tin and tantalum initiatives that we support. At the smelter, the conflict-free minerals from the DRC are blended with minerals from other conflict-free sources at a massive scale. The result is used to manufacture components for the Fairphone 2.

Have a look at this graphic to get a better idea of what happens to an individual mineral from the mine to the finished consumer product.

For the Fairphone 2, we will continue to work with Scaling Up the Mineral Trade and Solutions for Hope (which has always used a mass balance model) to source conflict-free tin and tantalum. We believe that it is essential to support initiatives like these, especially to demonstrate to the rest of the industry that responsible sourcing is possible in conflict-affected regions.

Assessing the impact of conflict-free mineral initiatives

Traceability and navigating the complexity of the supply chain are just a few examples of the challenges the industry is facing when attempting to set up projects that reinvigorate the mineral trade and support local economies in high risk areas. These early initiatives have succeeded in their initial goal of establishing the means and motivation to responsibly source minerals from the DRC.

However, there is still much work to be done to ensure real social impact at the local level. The next step needs to address more responsible mining practices and working conditions. On 17 August, an independent study was published that evaluates the benefits, challenges and lessons learned during three pilot projects in the DRC, including CFTI and Solutions for Hope.

One of the findings that we see as a clear recommendation going forward is that the actual ability of miners to negotiate and set prices is still very limited, for different reasons. This is not living up to expectations of the miners and creates tensions on the ground. For the future success of the project, this is one of the key issues that needs priority attention.

If you’re interested in learning more about the goals, outcomes and recommendations for the future of these initiatives, please download the full report.

Exporting conflict-free tungsten from Rwanda

For the Fairphone 1, we worked to integrate conflict-free tin and tantalum into our phone. With the Fairphone 2, we can take another step and further pursue our ambitions to source conflict-free tungsten from the African Great Lakes region. As a result of the Dodd-Frank Act’s reporting requirements, many companies started to only source their tungsten from countries like China, causing Rwanda’s tungsten trade to grind to a halt. However, that is about to change!

Following our recent research trip to Africa, we started engaging with suppliers such as KOTL (vibration motor manufacturer) and Tianjia (counterweight manufacturer), to discuss using tungsten from more responsible sources. Both were supportive of the idea, assuming that the material from the smelter met their specifications.

We’re currently working with Wolfram Bergbau to secure a permit to export conflict-free tungsten powder from Rwanda, which includes declaring that it will not be used for military or nuclear applications. The tungsten would first be shipped from Rwanda to Austria for smelting, and then on to China to be used in the production of our counterweights. Wolfram Bergbau would also use a mass balance model, similar to tin and tantalum. Because it takes 3 to 4 months to receive the permit, it might be too late to incorporate this tungsten into the first shipments of our new phones. Regardless, we’re committed to seeing this through going forward with the Fairphone 2 and helping to integrate conflict-free tungsten into the consumer electronics supply chain.

Research trip to Chinese gold mines

Finally, we are continuing our quest to identify fairer sources of gold. Our ultimate goal is to use more responsible gold in our products, such as fair trade or fair mined gold, but we’re not there yet. The first step is attempting to trace where the gold is sourced in components that will be used in the Fairphone 2, starting with the PCB. In July, we took a research trip to China with one of our suppliers to learn more about the gold mining and smelting process. Stay tuned for an in-depth report on our trip – we’ll publish a detailed blog post and video in just a few weeks.